All about CNC Machining Centers and Thermoforming for Plastics

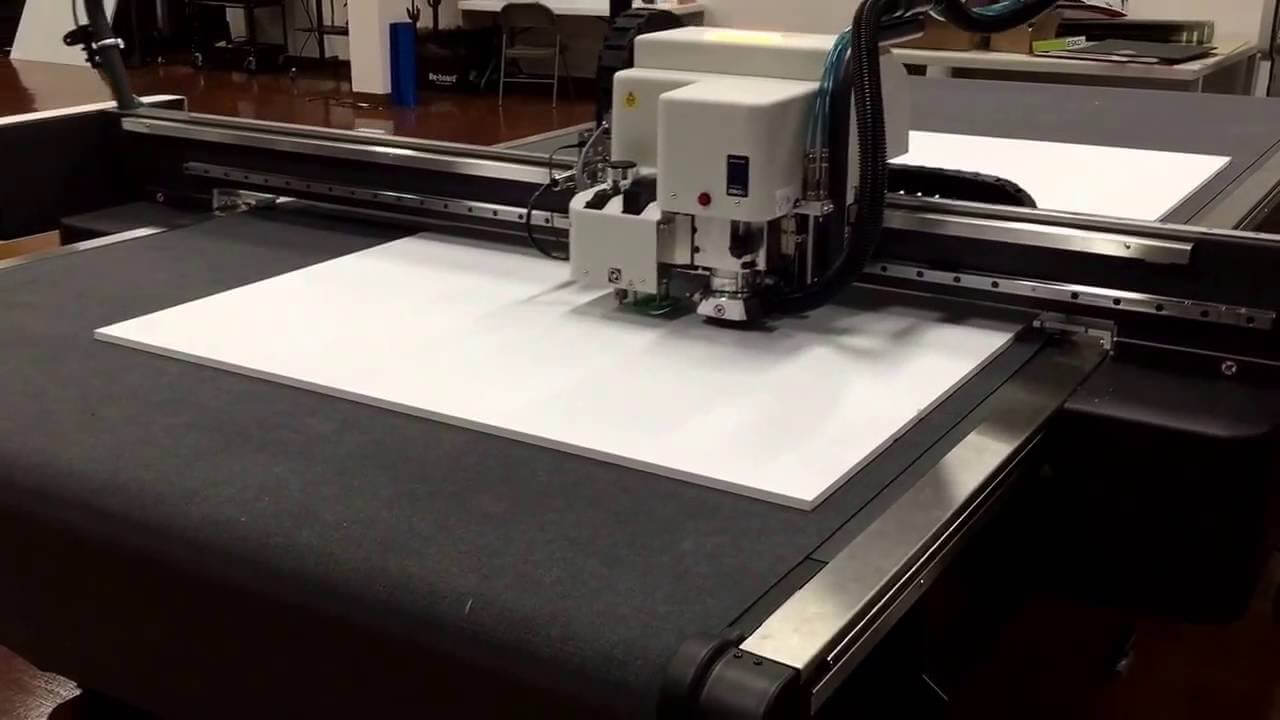

The CNC Router for Plastics and Foam Diaries

We've been supplying top-flight plastics & composite machining in southern California because 1970. Discover more about the various plastic products we can utilize at Upland Fab to create your parts. Discover More About our Plastics and Composites Machining We focus on machining complex plastic and composite parts. Our plastics are used for a variety of industries, from aerospace to electronic devices to industrial applications.

If you have concerns about your project's unique requirements or specifications, please call us to connect with one of our engineers today!.

The Of CNC Plastic Machining Services - Minneapolis & St Paul

Time to read: 5 minutes, So you've got a part to style, and the primary step is to determine what material it need to be made out of. You choose the part ought to be plastic, and it ought to be CNC machined, however does the choice stop there? Nope, there are a variety of plastics to pick from, each with its own mix of residential or commercial properties.

For the purposes of this short article, I'm going to narrow the choice to numerous of the plastic materials used by the Fictiv platform for CNC machining. For additional information on a wider selection of plastics for CNC machining, examine out Fictiv's complete range of capabilities on under "Materials" in the navigation.

CNC Plastic Machining - CNC Plastic Part - RapidDone

An Unbiased View of Useful Tips to CNC Plastic Machining - WayKen

If you understand your part ought to be plastic, but you're uncertain if it ought to be CNC machined or 3D printed,. ABS Plastic, Introduction, ABS is a well rounded general usage plastic. It provides high impact strength, durability, and electrical resistance at a low price. It is likewise simple to finish, as it can be easily painted, glued, or welded together.

3 Axis Desktop DIY Mini CNC 3018 Router Kit GRBL Control Plastic Acrylic PCB PVC Wood Carving Milling Engraving Machine Working Area 30x18x4.5cm - - Amazon.com

Benefits, ABS is an exceptional option for basic function prototyping, pre-molding models, parts that will receive effect and need toughness, or when low cost is desired. Downsides, ABS does not have excellent abrasion or chemical resistance and will melt in acetone. Answers Shown Here is also not an incredibly strong plastic. Furthermore, due to stricter ecological guidelines on the West Coast of the U.S., big pieces of ABS are just made in the Midwest and on the East Coast.